High-performance edge quality tailored to your device, assembly method, and downstream processes.

Focused on outcomes, not machinery.

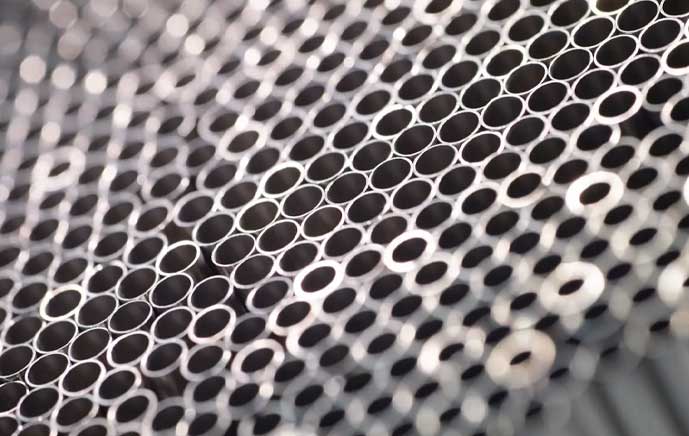

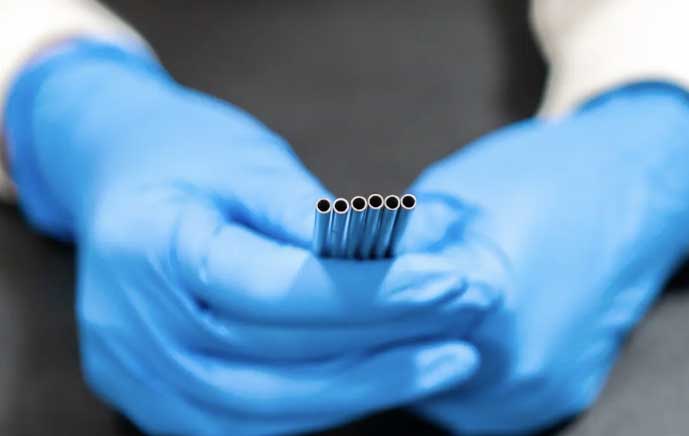

Cutting miniature tubing isn’t just about reaching a specified length, it’s about controlling how the tubing performs once it enters your assembly. Edge condition affects insertion forces, sealing surfaces, bonding, fluid flow, and even the ergonomics of how components fit together.

K-Tube provides cutting options engineered to give you the level of precision, cleanliness, and consistency your application demands.

Cut-End Options

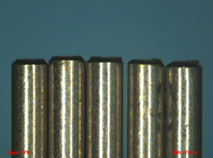

Factory Cut

A cost-effective, general-purpose option with a standard, unfinished production edge.

Best for:

- Applications where you’ll finish or machine the tubing in-house

- Prototyping and early-stage design

- Bulk cut-to-length material

- Processes where minor burrs do not impact performance

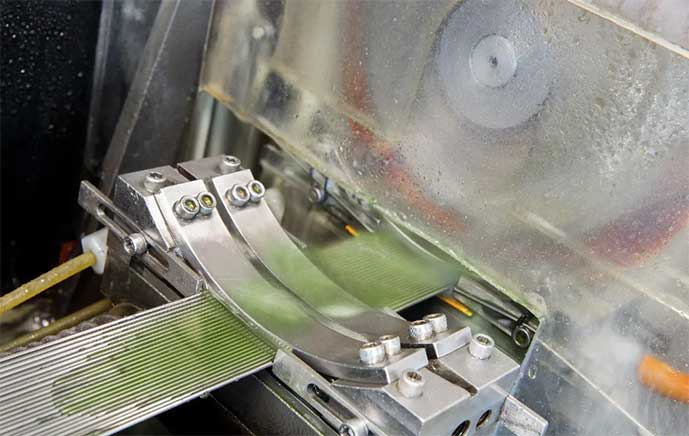

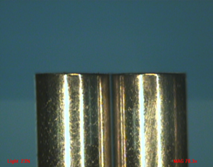

Machine-Feed Cut

A controlled cut ideal for automated systems requiring predictable edge quality and reliable tube presentation.

Best for:

- Automation feeding or bowl-feeding lines

- High-volume builds

- Situations where consistent lead-in geometry reduces equipment jams or rejects

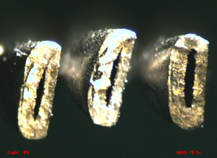

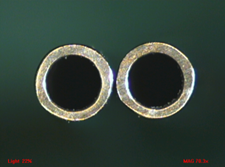

Premium Clean/Burr-Free Cut

Our most advanced cutting level, delivering precise, burr-free edges with near-zero particulates. Recommended for high-performance and high-regulation environments.

Best for:

- Medical device assembly

- Laser-welded or bonded interfaces

- Any application requiring clean, sharp geometry without mechanical stress

- Precision fits where edge variation affects functional performance

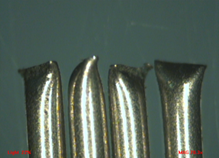

Material Matters: Edge Condition by Alloy

Different tubing alloys behave differently under cutting forces. Harder or spring-tempered materials may produce sharper edges, while softer materials may experience minor deformation depending on wall thickness and OD.

K-Tube’s engineering team considers:

- Alloy and temper

- Wall thickness

- OD range

- Required edge geometry

- Tolerance stack-up impacts

- Downstream cleaning or finishing

- Risk of galling, particle generation, or deformation

We adjust cutting approaches to ensure your edge meets functional requirements, not just dimensional ones.

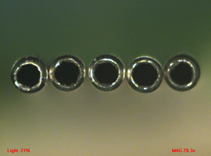

Secondary Finishing for Perfect Edges

If your design requires ultra-smooth or ultra-precise edges, we offer:

- Tumbling

- Deburring

- Light polishing

- Mechanical edge refinement

- Cleaning matched to the cutting level

These optional processes can dramatically improve assembly performance, user feel, or surface readiness.

Cutting FAQs

Cleaner cuts typically require higher precision and additional control steps. However, they may reduce your total cost by eliminating downstream finishing, lowering scrap rates, or preventing assembly delays.

Yes. Material hardness, stiffness, and spring characteristics influence burr formation and edge shape. We’ll help you choose the best cutting level for your alloy and geometry.

Absolutely. Our engineering team will guide you based on your tolerances, assembly method, and performance goals.

Get a Cut Recommendation

Share your specs and we’ll guide you to the ideal cut quality for your material, tolerances, and assembly needs.