Engineered precision for your most demanding applications. Tight-tolerance control, advanced drawing methods, and decades of manufacturing expertise—built to meet your specifications with confidence.

Why Dimensional Precision Matters

In tubing, precision isn’t just about fit—it determines performance, reliability, and regulatory compliance. Even the smallest dimensional variations can impact flow dynamics, insertion forces, assembly fit, or downstream processing.

K-Tube specializes in tight dimensional control across long production runs. Whether you need ultra-smooth IDs for interventional devices or consistent wall thickness for high-pressure heat exchangers, our process ensures repeatable, application-ready results.

Tight Tolerance Dimensional Control

Our precision processes allow us to achieve extremely tight ID and OD tolerances, often to within ±0.0005 in. — and maintain them across thousands of feet of tubing.

Why It Matters

- Reduces friction and insertion forces in medical applications

- Improves mechanical integrity and assembly fit

- Allows for unique product designs

Applications

- Medical hypotubes and interventional devices

- Aerospace heat exchangers and probes

- Precision industrial fluid transfer systems

- Components requiring consistent, high-performance ID/OD characteristics

Precision Drawing Methods:

Sink vs. Plug Drawing

The drawing method influences the tubing’s final geometry, material condition, ID finish, and tolerance precision. By offering both sink and plug drawing, K-Tube gives engineers the ability to dial in material properties through reduction percentage, achieving either higher strength or a softer, more formable tube depending on the design need.

Sink Drawing

Economical, fast, and ideal for many applications

Produces strong tubing with good dimensional control

Best for projects where ID finish is less critical

Plug Drawing

Involves drawing tubing over a mandrel (plug) inside the tube

Produces exceptionally smooth ID surfaces and tight tolerances

Ideal for applications that require low insertion forces, precise flow characteristics, or critical ID dimensions

Optional Processing Enhancements

Tailor Tube Performance for Strength, Flexibility, or Function

Not every application calls for standard tubing. Whether you’re coiling, welding, or crimping, K-Tube offers a range of processing enhancements that fine-tune your tubing for specific behaviors, environments, and assembly needs.

Annealing

Heat treatment to improve ductility — making tubing softer and easier to form, bend, or coil. Annealed tubing is ideal when you need it to hold a shape (such as after crimping) or when it’s being welded to other components.

Application Highlight:

Crimp tubes in surgical robotics and prosthetic devices often rely on annealed tubing to stay securely deformed after crimping without cracking.

Age Hardening (Or Precipitation Hardening) Heat Treatment

A controlled heat treatment process that increases the strength and hardness of your tubing — perfect for applications where durability and mechanical resistance are critical. This is especially useful for thin-walled tubing that needs to resist deformation under load or torque.

Application Highlight:

Support tubes that require increased strength to prevent deformation during use.

Homogenous Tubing (HT)

K-Tube’s proprietary process that transforms the microstructure of welded tubing, resulting in a consistent grain structure across the weld zone. The result is tubing that’s visually and structurally uniform; a high-performance alternative to seamless tubing at a fraction of the cost.

Ideal for applications where weld zone visibility, consistency, or precision is a concern, such as fluid systems, high-purity environments, or devices requiring tight ID surface control.

Application Highlight:

Gas chromatography columns in which impurities can hide in the seams and alter analytical chemistry measurements.

Surface Finishing & Cleaning

Whether you’re managing friction, flow, or contamination, we offer multiple finishing and cleaning methods to meet your performance or regulatory goals:

- Ultra-smooth IDs for catheter delivery systems or fiber optics

- We can adjust our ID lubricants to match your application, and we’re open to evaluating alternative chemistries as needed.

- Ultrasonic cleaning for removing particulates.

- Cleanliness standards vary by industry. Our team works with you to deliver the precision cleaning you need including medical, semiconductor, and analytical requirements.

Application Highlight:

Tube in tube medical devices in which low friction is required or fill and finish needles where cleanliness is imperative as a product facing material.

Straightening & Cutting

Need tubing in precise lengths and ready for downstream operations? We deliver straight-cut tubing in a variety of cut styles (shear, score break, electrolytic, laser) each optimized for edge condition, burr control, and cost efficiency. Combined with straightening and deburring, your parts arrive ready to drop into your build.

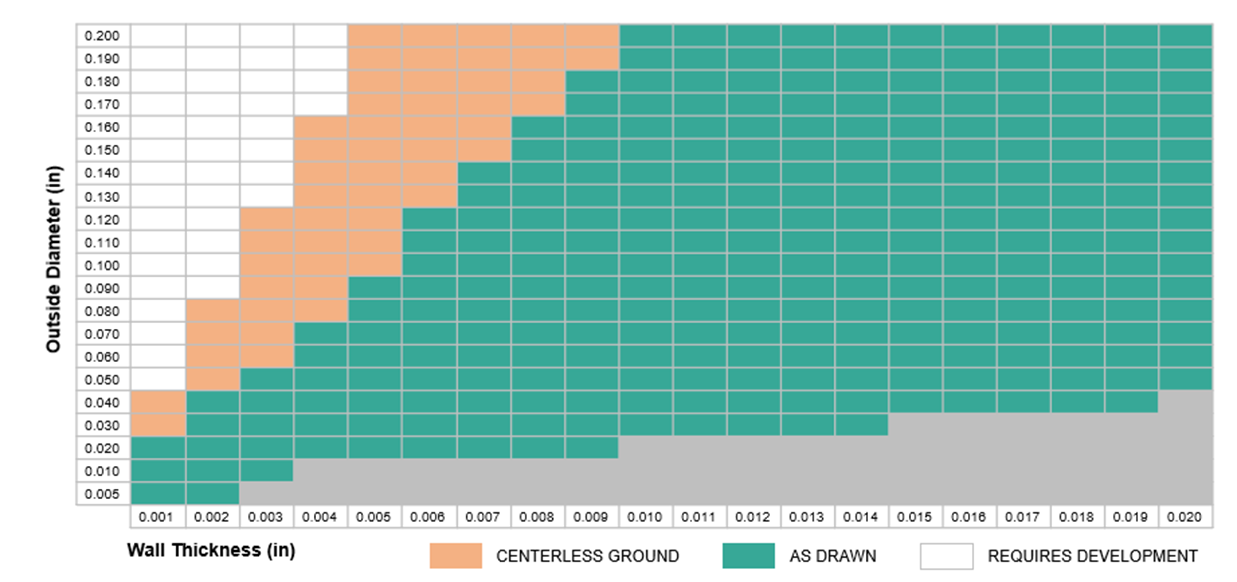

Download the Dimensional Tolerance Guide

Get a deeper look at tolerance ranges, drawing methods, and how to design with precision in mind.

Dimensional Capabilities Frequently Asked Questions

Sink drawing is more economical and faster but provides less control over ID finish. Plug drawing uses a mandrel to achieve superior ID smoothness and tighter tolerances, making it ideal for critical applications.

Depending on the material and size, we can hold tolerances as tight as ±0.0005 in. across long production lengths.

Smooth ID surfaces reduce insertion forces, improve device performance, and minimize debris or particulate contamination—critical factors for regulatory approval and patient safety.

Yes. We routinely work to customer-defined tolerances and can provide documentation, testing, and validation to support quality and compliance requirements.

Our continuous coil manufacturing allows us to maintain consistent tolerances across very long lengths, which is essential for applications like fluid delivery systems or coiled medical tubing.

Partner with K-Tube for Precision Tubing

Our dimensional expertise ensures your tubing performs exactly as designed—no surprises, no compromises.